A question many new turners ask is “how fast should I run the lathe?”. Read on and hopefully you will understand how to answer the question. Surprisingly many turners fail to give a straight answer and resort to comments like “what feels right” or “turn it up until it vibrates”. The first of those answers doesn’t really help a new turner because they have yet to develop that sense of what feels right and the second is fraught with dangers if the work piece is well balanced because you may not get any significant vibration until the safe working speed is significantly exceeded.

Does speed matter?

Why is it necessary to limit the speed of the lathe? There are two answers to this – one is to limit vibration for an out of balance piece and this may be the over-riding factor if the balance is significant. The second answer is that rotating anything introduces centrifugal force which is trying to pull the object apart. If there are any flaws in the wood (noticeable or otherwise) excessive speed may cause enough centrifugal force to cause the work piece to break up. This would lead to potentially large and heavy pieces of wood becoming projectiles – causing damage to anything and anyone in their path so be warned! It is also worth bearing in mind that the centrifugal force generated by the rotation of the work piece is proportional to the square of the speed (rpm’s). This means that doubling the speed would result in four times the centrifugal force; trebling the speed would result in nine times the centrifugal force and so on. It’s easy to see how excessive speed can lead to an accident.

Calculate the right speed

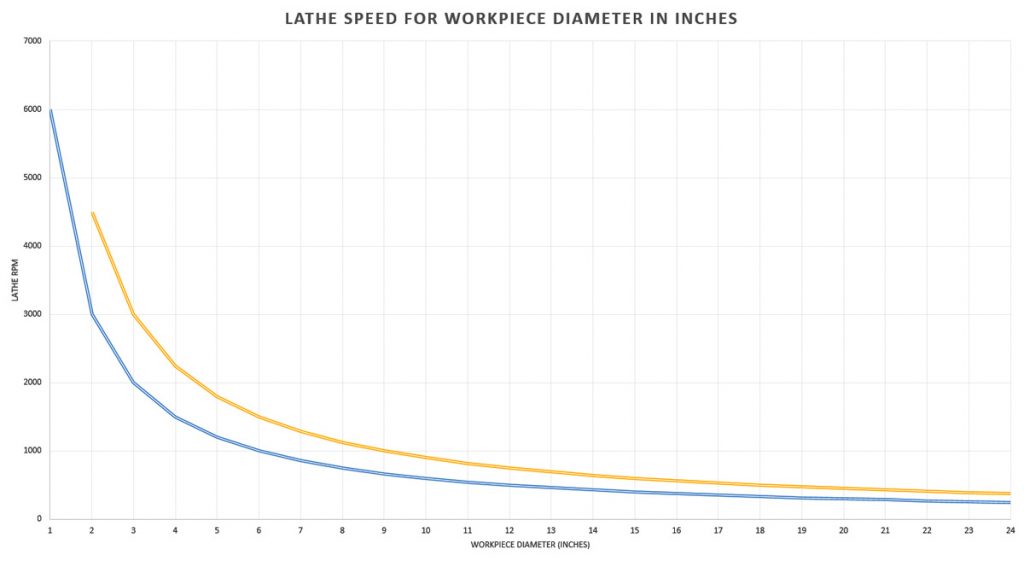

How do I calculate a safe speed to run the lathe? The answer to this one is fairly simple – if you work in imperial measurements, divide 6000 by the diameter of the work piece in inches to calculate the low rpm and divide 9000 for the high rpm. For example, a 3 inch diameter work piece would result in a speed of between 2000 and 3000 rpm and for a 10 inch diameter work piece the speed would be between 600 and 900rpm. If you want to keep this simple, just use divide into 6000 (ignore the 9000 bit!).

If you work in metric measurements, divide 15000 by the diameter of the work piece in centimeters to calculate the rpm. Below are example speeds for a range of diameters up to 24 inches.

| Workpiece Diameter (inches) | Speed (rpm) | Speed 2 (rpm) |

|---|---|---|

| 1 | 6000 | |

| 2 | 3000 | 4500 |

| 3 | 2000 | 3000 |

| 4 | 1500 | 2250 |

| 5 | 1200 | 1800 |

| 6 | 1000 | 1500 |

| 7 | 857 | 1286 |

| 8 | 750 | 1125 |

| 9 | 667 | 1000 |

| 10 | 600 | 900 |

| 11 | 545 | 818 |

| 12 | 500 | 750 |

| 13 | 462 | 692 |

| 14 | 429 | 643 |

| 15 | 400 | 600 |

| 16 | 375 | 562 |

| 17 | 353 | 529 |

| 18 | 333 | 500 |

| 19 | 316 | 474 |

| 20 | 300 | 450 |

| 21 | 286 | 429 |

| 22 | 273 | 409 |

| 23 | 261 | 391 |

| 24 | 250 | 375 |

The graph shows speed against diameter (in inches). For any diameter, pick a speed between the two lines.

What if there is vibration?

As mentioned earlier, the overriding consideration is keeping vibration to a minimum by limiting the lathe speed so in the case of severe vibration (usually caused by an out of balance work piece), keep the speed low enough to keep vibration to a minimum. This may be considerably less than the calculated safe speed.